We know the journey our cocoa beans take – from their origins all the way to our chocolateries around the world. Since we believe this is the only way to create the highest-quality chocolate, it is our top priority.

Our partners

We have one thing above all else in common with our partners – a passion for the highest quality – so it stands to reason that we’ve developed a few friendships over the years. These are friendships that we're happy to share with you; join us in visiting the farms, groves, and smallholdings.

Edwin Sibaya – cocoa farmer from Costa Rica

“We know the Läderach buyers personally, and we share their passion for chocolate.”

Go to interview

Fabio Francone – hazelnut producer from Piedmont

“They put their full trust in us, even in difficult harvest years.”

Go to interview

Werner Schenk – dairy farmer from Thurgau

“We also have our cows to thank for how beautiful Switzerland is.”

Go to interview

Our cocoa varieties

We source our cocoa from a range of countries around the globe – from Costa Rica to Madagascar. Even though all the countries along the cocoa belt have similar climates, the cocoa fruits harvested in each country develops individual and incomparable aromas and flavors.

Criollo

Criollo is often referred to as the queen of cocoa fruits. Due to a low yield, its beans are among the most sought-after in the world. Our Criollos come exclusively from two growing regions: the valley of Sambirano on Madagascar and the area around Upala in Costa Rica, both which offer an ideal environment for luxury cocoa. Gently fermented and dried, Criollo beans give the chocolate an intense cocoa flavor, paired with citrus and fruity berry notes.

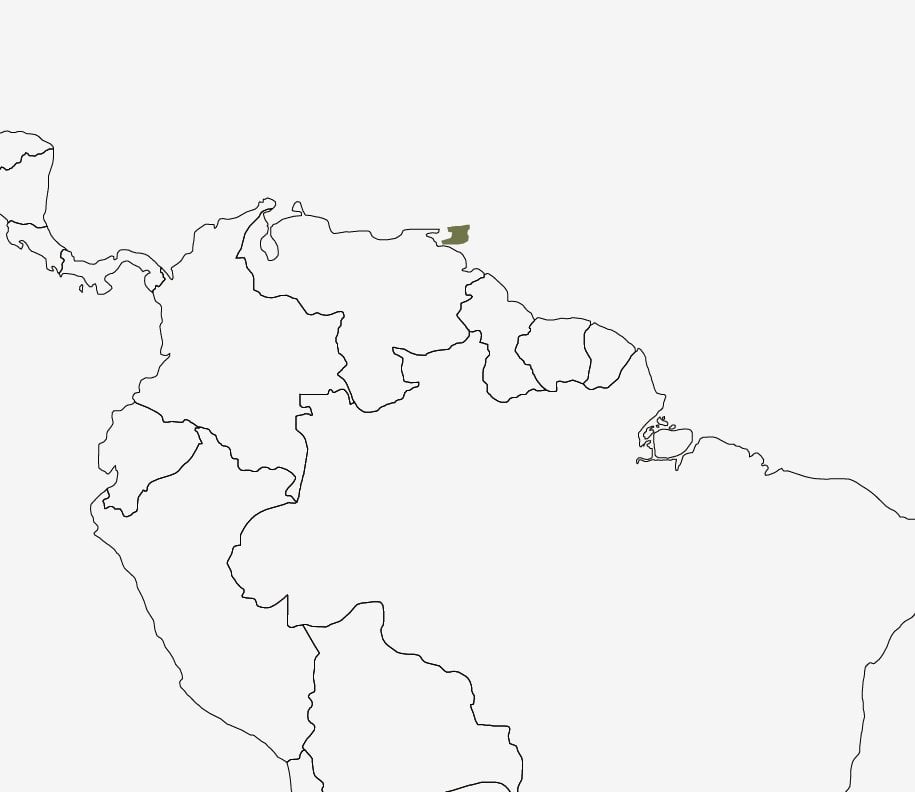

Trinitario

Our second luxury cocoa is Trinitario. We source these varieties from the same regions of Madagascar and Costa Rica we use to import Criollo, but also from Brazil – and Trinitarios original homeland of Trinidad. Our Trinitario from Trinidad comes from Gran Couva, fermented the traditional way and dried slowly, so that the beans produce an authentic Single Origin chocolate with a rich cocoa flavor and nuances of fine wood. In Brazil, the cocoa farmers use the Cabruca method. They ensure sustainable organic farming in the shade of the rainforest, preserving the natural ecosystem.

Amelonado

Amelonado is one of the most popular, slightly easier to cultivate varieties. Originally native to the Brazilian Amazon, the green and yellow cocoa fruits now grow on the African continent, too. Our Amelonado comes exclusively from Ghana and owes its highly aromatic and typical flavor profile not only to the fertile climate of the Central Region, but also to the experienced local cocoa farmers.

National

The National variety – also known by the name “Arriba” – is the pride of Ecuador. Like Criollo and Trinitario, it’s one of the traditional cocoa plants and used in our Single Origin Ecuador, among others. The beans for this come from the province of Los Rios – a water-rich terroir west of the main Andean ridge. Here in the Ecuadorian rainforest, the National variety thrives particularly well. It tastes slightly bitter and combines its intense cocoa notes with mild, floral aromas.

Imperial College Selection

The term “Imperial College Selection” (ICS) is used to refer to various different aromatic cocoa varieties selected and described in detail by Dr. F. J. Pound in the 1930s. Not strictly speaking a category of its own, it’s a selection of the finest cocoa types. The cocoa farmers grow ICS on the estates of Gran Couva. We buy the cocoa, which boasts impressive fruity-floral aromas and balanced notes, directly from the local Montserrat cooperative.

From origin to indulgence

We have been sharing our passion for fresh chocolate for generations. Discover more about our history, our innovations, and the authentic artisanal skills of our chocolatiers.

About us

The Swiss Alps are our home, and we invite the world to indulge in our culinary heritage. Find out where we come from and why innovation is so important to us. And get to know the people behind Läderach.

Learn more

World Chocolate Master

Elias Läderach is the only Swiss chocolatier to have earned the title “World Chocolate Master.” Experience his award-winning creations and find out more about his latest projects.

Learn more

House of Läderach

A chocolate museum, a chocolate studio, chocolate events – the House of Läderach has it all, including a café, of course!. Discover the delights of freshly made chocolate in all of its facets – 364 days a year.

Visit now

Freshness

The exquisite taste of our chocolate creations is an affair of the heart for us. That’s why we make them fresh daily and get them to you as quickly as possible – so you can experience the freshness with all your senses.

Learn more

Liechtenstein

Liechtenstein  Switzerland

Switzerland  Canada

Canada  United States

United States  Austria

Austria  Belgium

Belgium  Bulgaria

Bulgaria  Croatia

Croatia  Czech Republic

Czech Republic  Denmark

Denmark  Estonia

Estonia  Finland

Finland  France

France  Germany

Germany  Greece

Greece  Hungary

Hungary  Ireland

Ireland  Italy

Italy  Latvia

Latvia  Lithuania

Lithuania  Luxembourg

Luxembourg  Malta

Malta  Monaco

Monaco  Netherlands

Netherlands  Poland

Poland  Portugal

Portugal  Romania

Romania  Slovakia

Slovakia  Slovenia

Slovenia  Spain

Spain  Sweden

Sweden  United Kingdom

United Kingdom  Australia

Australia  Brunei

Brunei  Cambodia

Cambodia  China

China  Hongkong SAR of China

Hongkong SAR of China  India

India  Indonesia

Indonesia  Japan

Japan  Macau SAR of China

Macau SAR of China  Malaysia

Malaysia  Singapore

Singapore  South Korea

South Korea  Thailand

Thailand  Bahrain

Bahrain  Jordan

Jordan  Kuwait

Kuwait  Oman

Oman  Qatar

Qatar  Saudi Arabia

Saudi Arabia  United Arab Emirates

United Arab Emirates